Ellenex Conformal Coated Electronic Parts, A Difference That Matters

- Savio Navaratne

- Sep 7, 2023

- 4 min read

Introduction: A Splash of Science in the Tech Universe

Picture this: an intergalactic dance of tiny electrons, zipping and zapping through intricate circuits, powering the gadgets that light up our lives. But what if I told you that there's more to this electronic symphony than what meets the eye? Enter the mysterious realm of conformal-coated electronic parts – the unsung heroes of durability and resilience in the tech world. Buckle up as we embark on a journey to unravel the magic behind these hidden wonders!

Chapter 1: Cracking Open the Coating Conundrum

Imagine your smartphone as a fearless explorer, navigating a world of liquids, dust, and cosmic chaos. How does it brave this unpredictable environment without short-circuiting? The answer lies in conformal coating. Think of it as a superhero suit for your gadgets – a thin protective layer that shields delicate electronic components from the harsh elements they encounter.

Conformal coating is like a protective skin made of a thin plastic-like material that's put on printed circuit boards (PCBs). It's called "conformal" because it fits the shape of the PCB. This coating helps shield the PCB from things like water, dust, chemicals, and extreme temperatures. Nowadays, it's even used to stop tiny wire-like growths (called whiskers) and prevent current bleed between parts that are positioned next to each other.

Chapter 2: From Humble Beginnings to High-Tech Guardians

The history of conformal coating takes us back to the mid-20th century when engineers were already dreaming of waterproof gadgets. Early attempts involved dipping entire assemblies into protective substances like wax or oil – a bit like giving your phone a bubble bath! Thankfully, technology evolved, and now we have specialized coatings made from materials like silicone, acrylic, polyurethane, and even parylene (a super-thin polymer).

Chapter 3: The Fabulous Five; Types of Conformal Coatings

Silicone Shield

Like a second skin, silicone coatings offer fantastic protection against moisture and temperature extremes. They’re flexible, durable, and even provide a level of vibration dampening. Just like a chameleon, they adapt to their surroundings.

Acrylic Armour

Urethane Umbrella

Parylene Prestige

Epoxy Enchantment

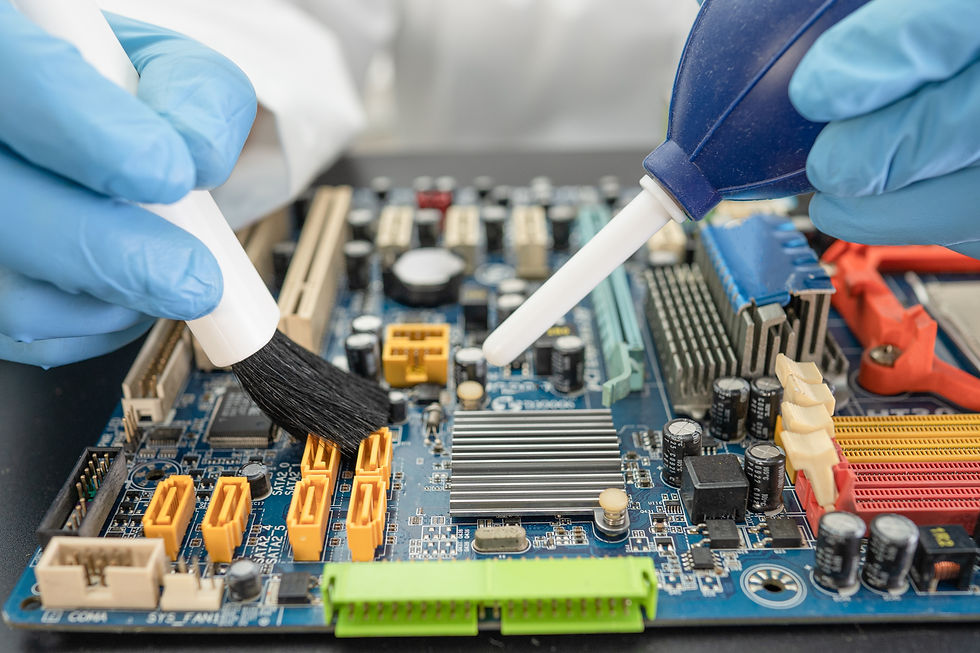

Chapter 4: The Top-Secret Application Process

So, how do engineers coat electronic parts without turning them into a gooey mess? It’s a delicate dance of precision! Picture a lab where skilled technicians apply coatings using methods like brushing, spraying, or dipping. The secret lies in controlling factors like viscosity, temperature, and curing time. It's like cooking up a masterpiece, but instead of a meal, you're serving up a safeguard for your tech treasures.

Chapter 5: The Power of Invisibility; Benefits Galore

Moisture Repellent Magic: Like a superhero deflecting bullets, conformal coatings repel moisture, ensuring your gadgets work even in the most humid of jungles or the rainiest of days.

Dust-Proof Charm: Just as Cinderella's glass slipper protected her foot, these coatings shield against dust, preventing it from clogging sensitive electronic components.

Chemical-Resistant Enchantment: Spills and splashes are no match for these coatings, which laugh in the face of chemicals that might otherwise corrode your beloved gadgets.

Temperature Tolerance Trick: From the hottest deserts to the coldest tundras, conformal coatings ensure your gadgets won't break a sweat (or freeze their circuits).

Based on a study conducted by Fortune Business Insights, the global market size for conformal coatings was valued at USD 899.1 million in 2021, anticipating a CAGR of 5.8% from 2022 to 2029, facilitating an increase from USD 940.8 million (2022) to USD 1392.8 million (2029). Furthermore, this growth study was based on their use in various automotive, consumer electronics, medical and aerospace & defence applications.

Chapter 6: The Dark Side; Drawbacks to Consider

While the world of conformal coated electronic parts seems like a realm of magic and protection, every enchanted tale has its darker side. Amidst the glimmering benefits, there are some shadows to be aware of. So, let’s venture into the land of cautious considerations:

Rework and Repair Difficulty

Once a component dons its conformal coat, making changes becomes a puzzle. Removing the coating requires the skill of a master magician, as even a small misstep can lead to delicate components becoming collateral damage.

Coating Conundrum

Heat Hurdle

Contaminant Confinement

Elusive Accessibility

Electricity’s Quandary

Costly Conjuring

Compatibility Spells Trouble

Thickness Tango

Time-Twisting Delays

Regulatory Runes

The top 5 vendors in conformal coating of electronics: Chase Corporation, Dow Corning, Henkel, Plasma Ruggedised Solutions, and VSI Parylene. ~By Business Wire.

Chapter 7: The Book of Potions: Regulations & Standards

IPC-CC-830C: Imagine IPC-CC-830C as the grand tome of all things conformal coating. This is the foremost standard that sets the stage for the enchantment to unfold. It stands as the guardian, qualifying different conformal coating products and revealing the secrets of materials, shelf life, curing, chemical properties, viscosity, and appearance requirements. It's a treasure chest of wisdom that even covers resistance against the mischievous fungus, moisture, and flames, along with vital electrical specifications like dielectric withstanding voltage.

IPC-A-610G: In the realm of electronic assemblies, IPC-A-610G is the spell book that defines what's acceptable and what's not. It dedicates a section to the art of conformal coating, specifically addressing coverage and thickness. Just as knights must wear their armor flawlessly, electronics assemblies must wear their coatings with precision, and this standard ensures they do just that. An example of ideal liquid conformal coating thickness values is:

Material | Thickness values |

Acrylic | 30-130 µm |

Polyurethane | 30-130 µm |

Silicone | 50-210 µm |

IPC J-STD001F: Picture IPC J-STD001F as a potion that brews the perfect soldered assemblies. While it may seem distant from coatings, it still has a section that deals with materials and application of conformal coatings. Just as a potion's ingredients must be mixed perfectly, the application of coatings requires meticulous attention to detail to ensure the final enchantment is flawless.

Chapter 8: Alchemy at Ellenex; How Conformal Coated Electronic Parts Impact Ellenex

Let’s turn our gaze inward and explore how this magical technology affects our company and its endeavours. Just as knights must adapt to the landscapes they traverse, so must we adapt to the advantages and challenges that these coatings bring.

Enhancing Durability and Reliability

By incorporating these coatings into our electronic parts, we bolster the longevity and reliability of our offerings, fostering customer trust and loyalty.

Elevating Brand Reputation

Mitigating Potential Drawbacks

Tailoring Solutions to Industry Needs

Balancing Cost and Benefit

Embracing Innovation and Adaptability

Collaborative Partnerships

Customer-Centric Approach

The world of conformal coated electronic parts is a landscape filled with both promise and challenges. As Ellenex sets forth on this journey, let us remember that every adventure requires courage, adaptability, and a dash of wizardry. By carefully considering the impact of conformal coatings on our products, brand reputation, and customer satisfaction, we at Ellenex, chart a course that leads to a brighter, more resilient future for our company and its offerings.

Conclusion: The Enchanted World of Conformal Coatings

In a world where gadgets are the real-life magic wands that shape our reality, it's easy to overlook the unsung heroes that keep them alive and kicking. It’s important to peer beyond the surface and understand the drawbacks alongside the benefits.

By weaving the previously discussed standards into our process, we align our efforts with the entire magical community of electronics manufacturing, setting a benchmark for excellence in the world of conformal-coated electronic parts. Conformal coatings, with their protective prowess, are the wizards safeguarding our electronic kingdom. So, next time you reach for your phone or flip open your laptop, take a moment to appreciate the invisible cloak of resilience that allows them to work their enchantment in our lives!